As an apprentice fitter / turner in the chemical industry, we had to learn all the skills of fitting and turning, from using a file to operating machine tools. We also learnt trade skills in other disciplines, fabrication, welding, instrument and electrical before going on to our chosen trade.

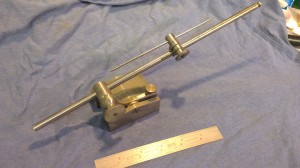

Part of the assessment process was to make various set pieces. One of the first was to make our own toolbox, then make some of the tools to put in it (some of which I still use today!) Here are photos of some of my apprentice pieces, they are not as rusty as they look in the photos! The 6″ rule is for scale.