Hi! Not posted for a while, over a year! Various things going on have got me out of the habit of posting stuff, but hopefully I will be posting regular again with a mix of CNC and manual machining.

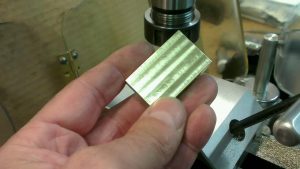

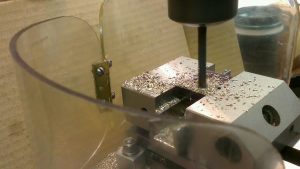

Here is a good example of the CNC/manual mix, this recent job is a ‘T’ shaped interface bracket for a robotic manipulator. Made of 12mm thick aluminium it needed drilling and countersinking. 6mm positioning dowels were used to give a rigid precise fixing. The circular recess is 2mm deep to enable the robot arm to locate securely, and is also dowelled and bolted into place. The two green/black foam pads are suction devices which will hold slabs of wood which will be positioned by the robot into two stages of machining.

I used the KX1 to CNC mill the circular pocket and to spot drill the holes. Then I used the manual milling machine to drill and countersink the holes. The 6mm dowel reamed holes were also done on the manual mill. After a quick file and polish with scotchbrite to give it a uniform finish everything fitted together great!